Having the best drone motors, ESCs and propulsion system on your UAV will give you longer flight times, exceptional flight stability and more precise flying. A top quality drone motor will be quieter, have a better cooling system and will last longer.

Drone motors along with electronic speed controllers and propellers are all vital components within a drone’s propulsion system. These are all critical to the performance and also safe flying of the drone or quadcopter.

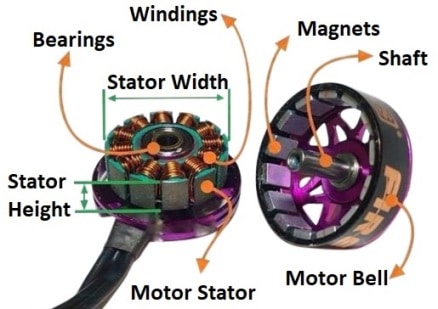

Below, we show you how drone motors work including the components of a drones propulsion system along with their design. This includes breaking down the drone motor into it’s components such as stator, motor bell, windings and bearings.

We also look at Electronic Speed Controllers (ESC) and propeller design, along with how motors are kept cool. Along with motor design, we look at how the propulsion system is protected in various environments and weather.

Throughout this post, there are plenty of videos to further explain about drone motors and how propulsion systems work.

Closer to the end, we list some of the best drone motors including ESC and propulsion system manufacturers.

Drone Propulsion System Parts And Design

Now, lets take a look a the main components and parts of a drone motor. We will use a DJI E7000 propulsion system and others drone motors as examples.

The main components of the drone motor and propulsion system are as follows;

- Motor Stator

- Motor Bell (rotor)

- Windings

- Bearings

- Cooling System

- Electronic Speed Controllers

- ESC Updater

- Propellers

- Wiring

- Arm

How Drone Motor And Propulsion System Work

Drone Motor Stator

The motor stator is the stationary part of a rotary system, found in electric motors, The main function of the stator is to generate the rotating magnetic field. The stator frame, stator core and stator winding are the three parts of the stator.

Drone Motor Bell

The motor bell is the part of the drone motor which rotates. On a quadcopter, which has 4 motors, you will have 2 clockwise (CW) and 2 counter clockwise motors (CCW). In other words the motor bell works by rotating clockwise or counter clockwise depending on its configuration.

The props on a quadcopter will also be clockwise (CW) or counter clockwise (CCW) and must be matched with the drone motor.

Most quadcopter props are designed so that the CW prop will only fit onto the CW motor and the same for the CCW props.

Air Gap (Between Stator & Rotor Bell)

The distance between the rotor and stator is called the air gap. The air gap has important effects and is generally designed to be as small as possible. A large air gap has a strong negative effect on performance.

The air gap is the main source of the low power factor at which motors operate. The magnetizing current increases with the air gap. For this reason, the air gap should be minimal.

Drone Motor Windings

The windings in electric motors are copper wires, which are laid in coils. There are generally wrapped around a coated soft iron magnetic core to form the magnetic poles, when energized with current.

Fixing A Drone Motor And Repairing Windings

A drone motor might need to be repaired or replaced for the following reasons;

- Motor stops working completely

- Not rotating

- Motor is skipping or kicking

- Stuttering or response lag

- Windings could be broken

- Burnt windings

- Sounding not right

- drone not flying correctly

How Drone Motor Winding Work Video

This 1st video shows how to repair the windings on a RC motor and gives very good explanations on how the motor windings work.

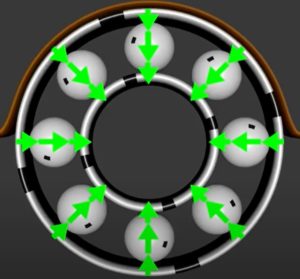

How Drone Motor Bearings Work

The concept and how bearings work in a drone motor is very simple. Most things in general roll better than they slide. When things slide, the friction between them causes a force, which slows them down.

The concept and how bearings work in a drone motor is very simple. Most things in general roll better than they slide. When things slide, the friction between them causes a force, which slows them down.

However, if the two surfaces can roll over each other, the friction is greatly reduced.

Bearings reduce friction by providing smooth metal balls or rollers, along with a smooth inner and outer metal surface for the balls to roll against. These balls or rollers “bear” the load, allowing the device to spin smoothly.

The purposes of a bearing in an electric motor is to support and locate the rotor, to keep the air gap small, consistent and transfer the loads from the shaft to the motor.

The bearings should be able to operate at low and high speeds, whilst minimizing frictional loses. At the same time, the bearing must be economic and require no maintenance in the drone motor.

Over 50% of motor failures are down to bearing failures so the bearings are a very critical component of a drone motor.

Drone motors use shielded bearings. These bearings restrict contamination from getting into the rolling elements at installation and during operation. The shields help to retain the lubrication in the bearing chamber.

Here is a terrific video, which shows you how motor bearings work with great explanations. This video shows you how to make your own ball bearing motor.

Drone Motor Design

Drone motors and propulsion systems are designed to be light, strong, balanced and efficient using as little battery power as possible. The more energy efficient the motor is, then flying time is increased or a heavier payload can be added. Drone propulsion systems also need to produce as little vibration as possible.

The motors, ESC including wiring also need to be protected in all types of weather and in various working conditions.

Let’s take a look at how the drone motor and propulsion system is designed.

How Drone Motor Cooling System Work

Every motor needs to be designed to prevent the build up of excessive heat, which will damage the motor, the Electronic Speed Controllers and wiring. Many drone motors are designed using a centrifugal cooling system, along with cooling fins.

Every motor needs to be designed to prevent the build up of excessive heat, which will damage the motor, the Electronic Speed Controllers and wiring. Many drone motors are designed using a centrifugal cooling system, along with cooling fins.

High end drone motors like the KDE10218XF-105 for heavy lifting and long flight drones have an integrated centrifugal fan.

Drone Motor Protection Against Weather & Surroundings

For a drone to fly outdoors in all weather conditions, the drone motor and components need to be weatherproof. The motors also needs to be protected against dust, debris and corrosion.

Top drone motors and components are permanently bonded and sealed internally. They will have a weatherproof sealant to cover the motor bearings system and the ESCs (Electronic Speed Controller). Another coating is applied to the drone motor stator.

These sealants protect the drone motor, the ESCs, wiring and its circuits from rain, rust, corrosion and dust. If the UAV is used as an agricultural drone for spraying crops, it will be sealed for protection against the pesticide spray.

Drone Motor & Component Protection

When reading the specification for drone motors and ESCs, look for the IP code (Ingress Protection code) rating.

The IP Code (Ingress Protection code) classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact and water. The IP code standard aims to provide a more detailed information rather than terms such as ‘waterproof’.

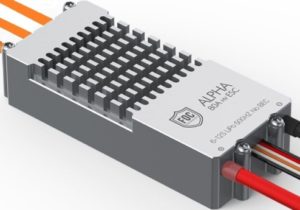

For example, the ALPHA 40A LV ESC (electronic speed controller) from T-Motor has a rating of IP55, which is protection from dust and water jets.

The DJI E5000 propulsion system (Motor, ESC, Props) has a rating of IP66. This means the E5000 drone propulsion system is protected against water projected in powerful jets (12.5 mm nozzle) at the motor from any direction without any harmful effects. It is also dust tight.

Drone Electronic Speed Controllers (ESC)

How Basic Electronic Speed Controllers Work

An electronic speed control or ESC is an electronic circuit, which controls and regulates the speed, acceleration and deceleration of the drone motors. Many ESCs also provide reversing of the motor and dynamic braking.

An electronic speed control or ESC is an electronic circuit, which controls and regulates the speed, acceleration and deceleration of the drone motors. Many ESCs also provide reversing of the motor and dynamic braking.

The latest high end ESCs on quadcopters use FOC (Field-Oriented Control) algorithms for more responsiveness and precision control of the motor. FOC can also be implemented on the actual ESC hardware.

FOC uses current control to control the torque of 3 phase motors and stepper motors with high accuracy and bandwidth. Alpha ESCs from T-Motor all use FOC technology.

The ground station remote controller sends data signals to the drone’s flight controller, which then forwards the signal to the ESC and then on to the drone motor.

Drone Motor And ESC Wiring

In general, the following cables are part of the ESC and drone motor configuration;

- ESC to motor connector wires (3 wires and can be various colors)

- Drone motor wires to ESC wires (3 wires and generally red, yellow and black)

- Power connector wires (1 red and 1 black)

- Connector to Flight Controller for ESC signal (black and white wire)

ESC Updater

When you buy one of the latest top drones, the manufacturer will release firmware upgrades every few months. The firmware updates with add new features to the drone and also fix any software bugs in the drone. The updates could fix or add features to any part of the quadcopter such as flight controller, gimbal, camera and even remote controller.

It is the same if you buy many ESC. The come with a component called the ESC update which allows for the electronic speed controller to have the firmware updated in the ESC. The DJI E1200 propulsion system contains an ESC updater.

How ESCs Work

This next video discusses all about ESCs and how ESCs work.

High Tech Smart Electronic Speed Controllers

Along with changing the speed of the motors, direction and braking, top of the range ESCs have a lot of intelligent and safety features added.

Let’s take a look at 2 top electronic speed controllers on the market and see what extra technology they include.

DJI Takyon Z14120 ESC

Here are some of the Takyon Z14120 ESC features;

- Black Box – flight data recorder.

- Voice Alarm – alerts the pilot of system failures caused by the ESC.

- Dual Throttle Systems – when used with DJI Flight Controllers (DJI N3 , DJI A3).

- Environment Protection – waterproof, dust proof and anti-corrosion (IP66 rated).

This Takyon Z14120 includes 2 x DJI 32 bit single core processors, giving the ESC realtime monitoring, precision motor control and an extremely fast response. If the 2nd processor is not required, it will go to sleep to reduce overall energy consumption. When the 2nd processor is required, it will restart operation to maintain the high overall performance.

ESC Monitoring

Along with the above features, the Takyon Z14120 electronic speed controller will monitor voltage, current, temperature, interior humidity and other critical parameters in realtime.

It prevents the drone going over voltage, over current, overheating and internal short circuits. The motor is also protected from being blocked and phase breaks.

This realtime monitoring system provides all round protection and reduces losses caused by malfunctions. A special spark proof circuit design prevents connectors from sparking when hot-plugging batteries, increasing plug wire durability and reducing maintenance time and cost.

ESC Heat Dissipation

A new heat dissipation technology developed specifically for the Takyon Z14120 ESC allows high powered drones to fly more steadily.

Using a patented heat dissipation technology, power MOSFET increases thermal conductivity to the outer shell by up to 20 times, compared to the use of traditional copper sheet. It allows high powered aircraft to operate for up to a full day without adding any fans.

KDE-UAS125UVC-HE ESC

Here are some of the features of the KDE-UAS125UVC-HE ESC;

KDECAN – enables live telemetry feedback with the flight controller for added safety and operation. Critical system components can be monitored in real time and additional control signals can be sent to the ESC.

Data Logging – through using a high memory storage, onboard EEPROM, which allows for continuous logging of critical parameters (voltage, amperage, temperature, throttle signal, throttle output, eRPM, etc.) with the ability to download and review via standard PC to USB connection.

Regenerative Braking – active braking during motor deceleration phase, providing instantaneous response to the flight controller commands

Temperature Controlled Synchronous Rectification – a new algorithm for smooth running of motors at low throttle, improved faster response under high peak loads, while significantly increasing flight time efficiency and reducing operating temperatures. This is sometimes termed active-freewheeling (Brushless DC Electric Motor DLDC active freewheeling“).

Active Monitoring – internal hardware and specialized algorithms continually monitor voltage, current, temperature, stall detection and many other critical parameters for safe reliable operation and damage prevention.

Dynamic Timing and Startup Power – optimally tuned for smooth and precision controlled startup throughout the full range of UAS Brushless Motors (no hesitation, stuttering, or response lag).

Increased Drive and Throttle Frequency Resolution – high-accuracy, linear throttle response throughout full range of operation control.

Motor Synchronization – factory calibrated ESCs for consistent throttle control and frequency-matched start-up protocols.

Anti-Spark Circuitry – protects the integrity and lifespan of critical connectors upon each initial plug in and system power up.

So, you can see that these ESCs have many intelligent functions to fly and also assist keeping the drone safe in flight.

Drone Arm

The drone arm is part of the design look and feel of the drone or quadcopter. Also, the drone arm contains critical wiring from the main flight controller board in the body of the drone to the ESC which may also be in the drone arm or seated at the bottom of the drone motor.

How Drone Propellers Work

To move forward, you need to push backward. This law of physics was first described in the 18th century by Sir Isaac Newton’s third law of motion (sometimes called “action and reaction”). It is the essence of anything which moves, including drones and how their propulsion systems are designed.

Drone Motor Propeller Design

Propellers, often shortened to “props,” and sometimes called “screws” are used to push the drone forward by sending a mass of air behind it. The prop pulls the air into it and push it out the far side. It is the same when the drone is going vertically up, the propellers push the air below the drone.

In whatever direction the quadcopter wants to fly, the air needs to be pulled in through the propellers and pushed out in the opposite direction.

Drone Propeller Strength

High quality propellers like the DJI E7000 propulsion system use a material called Ultra Carbon Pro for maximum strength and stiffness.

Many propellers from T-Motor are made from CF+Epoxy. CF is carbon fiber and Epoxy resin is the protective coating.

Propellers come in various sizes and design whether they are for quadcopters, multirotors and fixed wing aircraft. Other factors for drone propellers depends on what the drone is being used for. For example, the drone could be for FPV racing, carrying cameras or sensors such as Lidar or ToF sensors.

Angled Propeller Blades

Propeller blades are fixed at an angle to the shaft. This is called the pitch (or pitch angle) of a propeller and it determines how quickly the propeller moves the drone forward when it is turned and how much force you have to use in the process.

The angle of the propeller blade and its overall size and shape affect the thrust, along with the speed of the drone motor.

Here is one of the best videos, which explain everything about propellers and how propellers work.

How A Quadcopter Motor Rotates When Flying

Because quadcopters have 4 motors facing upwards, the work of the drone motors and propulsion system is very different from a fixed wing aircraft.

Because quadcopters have 4 motors facing upwards, the work of the drone motors and propulsion system is very different from a fixed wing aircraft.

Quadcopters use motor speed and propeller direction for propulsion. The propulsion system controls the force of gravity against the aircraft and also controls the air through the propellers.

Quadcopter Flying Along Vertical Plane

A quadcopter can do three things in the vertical plane: hover, climb, or descend.

- Hover Still

- Climb Ascend

- Vertical Descend

Drone Propulsion System For Yaw, Pitch And Roll

A quadcopters in flight is also free to rotate in three dimensions;

- Yaw

- Pitch

- Roll

The CW and CCW drone motors receive various combinations of speed signals from the flight controller to the ESCs to slow or speed up, which affect the drones flight movements.

You can read further on how CW and CCW motors speed is adjusted to fly and to Yaw, Pitch and Roll in our article entitled “How A Quadcopter Flies“.

How Drone Motors And ESCs Work – Video

Before look at the best drone motors and propulsion systems manufacturers, here is an excellent video on how Brushless motors work along with ESCs.

Buying Drone Motors And Propulsion Systems

Many of the drone manufacturers including the below manufacturers will recommend buying the full propulsion system which will include the drone motor, ESC and propellers. They will also give options for propellers to work with their various systems. They many also recommend flight controllers which work their propulsion systems.

It’s very useful to study the drone motor specifications to find out which ESC and propellers will work with drone motor. If you can’t find the details, then contact the manufacturer.

Companies like DJI and T-Motor generally supply everything including fight controller which make the finding the right propulsion system easy.

Best Drone Motors And Propulsion Systems

Here are the top drone motors, ESCs, propulsion systems manufacturers and suppliers.

- KDE

- T-Motor

- Lumenier

- MAD

- iFlight

- DJI

Now, lets take a closer look at these top drone motor manufacturers.

KDE Direct

KDE Direct is a US company based in Oregon and was founded by Leslie Koegler. They are a leading manufacturer of brushless motors, electronics and components for the UAV market for over a decade. KDE Direct remains the leading choice for military, industrial, and commercial businesses.

They are continually designing larger and more powerful motors for markets, which needs more thrust and ever increasing reliability. KDE is also designing and testing new propellers for more strength and durability.

Here are the links to the KDW pages for their drone motors, ESCs and propellers.

T-MOTOR

Founded by a model airplane specialist called Wu Min, T-MOTOR have been providing propulsion system solutions for UAVs since 2007. This Chinese company specialize in drone motors, ESCs, flight controllers, drone arms and propellers.

They have large collection of propulsion systems used in aerial photography along with many industrial, agricultural and commercial applications.

One of the top products is the U15 II KV80 heavy lift drone motor with a max thrust of 79 lbs (36 kg).

Lumenier

Lumenier is a US based drone design and manufacturing company located in Sarasota, Florida. They have been around since 2011 and are now a global leader in small UAS and unmanned ground vehicles for both defense and commercial applications.

Lumenier is a US based drone design and manufacturing company located in Sarasota, Florida. They have been around since 2011 and are now a global leader in small UAS and unmanned ground vehicles for both defense and commercial applications.

They manufacture brushless drone motors, ESCs, Props, FPV airframes, flight cameras, FPV transmitters, antennae, flight controllers and a lot more.

The Lumenier drone motors have been engineered from the ground up with beautiful elegant design and high end performance. By using high quality bearings and CNC precision machined parts, each Lumenier motor provides smooth and reliable power.

One of its best drone motors is the Lumenier 2207-7 1750 KV JohnnyFPV V2 motor.

The 2207 was named after and inspired by FPV drone pilot Johnny Schaer (AKA Johnny FPV), matching his smooth and aggressive flying style. This motor use a more powerful stator in combination with N52SH magnets and very small air gap, resulting in incredible power and performance.

MAD Components

MAD Components designs, develops and manufactures propulsion systems for wide range of multirotor UAVs. They ship worldwide and have offices in Warsaw Poland and Hong Kong.

MAD produce large heavy duty motors like the MAD M30 100 KV, with a max thrust up to 55 lbs (25 kg). They also produce smaller drone motors for FPV racing including the MAD 2306 series.

iFlight

iFlight Innovation Technology Limited was founded in March 2014. It is located in Huizhou, Guangdong Province, China.

They manufacture very popular FPV racing drones, Wings, Planes, UAV drones, Flight Control Systems, ESCs, Brushless motors, FPV cameras, Video transmitters and Gimbals.

iFlight are well known for their FPV racing and Whoop drones which are fast, reliable and terrific fun.

DJI

DJI supply approximately 70% of the consumer and commercial drone market. Their latest drones are the Mavic Air 2 and the Mavic Mini. Their high end industrial drone is the Matrice 300 RTK.

They are a Chinese Company with its headquarters in Shenzhen and have offices in the United States (Los Angeles), Germany, Netherlands, Japan, South Korea, Beijing, Shanghai, and Hong Kong.

Along with the top of the range drones, DJI manufacture Propulsion systems, which include the motor, ESC and propellers.

The DJI Propulsion systems are of exceptional quality and designed for heavy duty industrial applications. DJI also manufacture the Takyon ESC and Flight Controllers.

With DJI supplying the full propulsion system and flight controllers, you have everything for the UAV solution you need.